Synthetic Fibres

Origins, Properties, and Environmental Impact

Synthetic fibres have revolutionized the textile industry with their versatility and cost-effectiveness. Derived primarily from petrochemicals, these fibres offer a range of properties suited for various applications. However, their production and disposal raise significant environmental concerns. This article explores the different types of synthetic fibres, their properties, pros and cons, production processes, environmental impacts, and challenges in recycling.

Types of Synthetic Fibres

- Polyester

- Nylon

- Acrylic

- Spandex (Lycra)

- Polypropylene

(There are many more but there are the most common ones).

Derivation and Production Process

Polyester

- Derivation: Derived from petroleum-based chemicals, mainly ethylene glycol and terephthalic acid.

- Production: Polymerization creates polyethylene terephthalate (PET), which is melted and extruded into fibres.

Nylon

- Derivation: Made from petroleum products, primarily through the polymerization of caprolactam or hexamethylene diamine and adipic acid.

- Production: Polymerized into nylon 6 or nylon 6,6, melted, and extruded into fibres.

Acrylic

- Derivation: Derived from acrylonitrile, a petroleum-based compound.

- Production: Polymerization of acrylonitrile, followed by extrusion into fibres.

Spandex (Lycra)

- Derivation: Made from polyurethane, a synthetic polymer.

- Production: Polymerization of diisocyanate and polyester/polyether, resulting in a stretchable fibre.

Polypropylene

- Derivation: Derived from propylene, a by-product of petroleum refining.

- Production: Polymerization of propylene, followed by extrusion into fibres.

Properties, Pros, and Cons

Polyester

- Properties: Durable, resistant to shrinking and stretching, quick-drying.

- Pros: Versatile, wrinkle-resistant, cost-effective.

- Cons: Non-biodegradable, prone to pilling, less breathable.

Nylon

- Properties: Strong, elastic, abrasion-resistant.

- Pros: Durable, lightweight, quick-drying.

- Cons: Non-biodegradable, can retain odors, high static.

Acrylic

- Properties: Soft, warm, lightweight.

- Pros: Wool-like feel, resistant to moths, easy to dye.

- Cons: Prone to pilling, less breathable, non-biodegradable.

Spandex (Lycra)

- Properties: Highly elastic, strong, lightweight.

- Pros: Excellent stretch, shape retention, durable.

- Cons: Sensitive to heat, non-biodegradable, can degrade over time.

Polypropylene

- Properties: Lightweight, resistant to chemicals and moisture.

- Pros: Insulating, quick-drying, resistant to mildew.

- Cons: Low melting point, non-biodegradable, can be less comfortable.

Energy and Water Consumption in Production

Synthetic fibre production is energy-intensive, often requiring high temperatures and complex chemical processes. The production of polyester, for example, consumes significant amounts of energy due to the high-temperature polymerization process. Water use is generally lower than natural fibres, but the chemicals and dyes used can lead to water pollution.

Environmental Impact

Manufacture

- Pollution: The production process releases greenhouse gases and pollutants, contributing to air and water pollution.

- Energy Use: High energy consumption due to reliance on fossil fuels.

- Chemical Use: Use of toxic chemicals in production and dyeing processes.

Disposal

- Non-biodegradable: Synthetic fibres take hundreds of years to decompose, contributing to landfill overflow.

- Microplastic Pollution: Fibres shed during washing can enter waterways, harming marine life.

- Recycling Challenges: Difficult to recycle due to mixed fibre compositions and degradation of quality during recycling processes.

Conclusion

Synthetic fibres, while offering durability and versatility, present significant environmental challenges from production to disposal. The reliance on fossil fuels, high energy consumption, and issues with biodegradability and recycling underscore the need for more sustainable practices and innovations in fibre production and waste management.

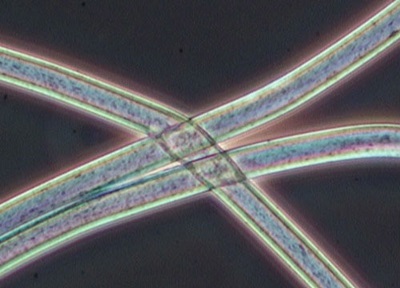

Image: Polyester fibres under a microscope (Dreamstime.com)

This comprehensive overview addresses the origins, properties, and environmental impact of synthetic fibres, providing valuable insights into their role in the textile industry and the associated sustainability challenges.

Links: The Dangers of Synthetic Fibers and Fabrics on the Environment – Superego (superegoworld.com)

One reply on “Synthetic Fibres”

[…] on the fibre types i.e. the raw materials that fabrics are made from, read my blogs on natural, synthetic and man-made […]