Understanding Fabric Construction

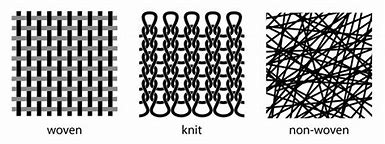

Fabric construction is the foundation of all textiles, determining the look, feel, and behaviour of the fabric. There are two primary methods of fabric construction: weaving and knitting. Both offer a wide range of fabric types, each with unique qualities suited for different purposes. Let’s take a closer look at these methods and some common structures within each.

Weaving

Weaving involves interlacing two sets of yarns at right angles: the warp (vertical yarns) and the weft (horizontal yarns). The pattern in which these yarns intersect creates different fabric structures. Here are a few common types of weave:

- Plain Weave: The simplest and most common structure, where each weft thread crosses over and under warp threads in a uniform pattern. Examples include cotton poplin and muslin.

- Twill Weave: Characterized by diagonal ridges or ribs, twill is a durable and sturdy structure. Denim is a famous example of twill weave.

- Herringbone and Houndstooth: These are variations of twill weave. Herringbone features a V-shaped zigzag pattern, while houndstooth has a broken check pattern, often used in suiting fabrics.

- Satin Weave: Known for its smooth, shiny surface, satin weave involves floating weft threads over multiple warp threads, creating a lustrous finish.

Each weave structure results in a different texture, strength, and drape. Weave variations are often used in clothing, upholstery, and other textile products.

Knitting

Knitting creates fabric by interlooping yarns in a series of connected loops. The flexibility and stretch of knitted fabrics make them ideal for garments like T-shirts, sweaters, and leggings. Below are a few common knit structures:

- Single Jersey: A lightweight knit with loops on the front and a flat back. It’s commonly used for T-shirts and casualwear.

- Double Knit: This structure is thicker than single jersey, with identical faces on both sides. Double knit fabrics, like Ponte de Roma, are more stable and structured, making them perfect for garments like dresses and blazers.

- Interlock: A variation of double knit, interlock is soft and smooth, often used in activewear and children’s clothing due to its comfort and durability.

Non-Woven Fabrics

In addition to woven and knitted fabrics, there is a third category: non-woven fabrics. These fabrics are not created by interlacing yarns but rather by bonding fibres together through heat, chemical, or mechanical processes. Non-wovens are typically used for industrial applications but also play a role in the garment industry.

- Fusible Interfacing: A well-known example of non-woven fabric, fusible interfacing is used to add structure to garments, particularly in collars, cuffs, and waistbands. It is heat-bonded to other fabrics to reinforce or stiffen them.

- Felt: Though traditionally made by matting wool fibres together, modern synthetic felts are non-woven fabrics used in some accessories like hats and decorative embellishments.

- Synthetic Suede (e.g., Ultrasuede): A non-woven fabric that mimics suede’s appearance and texture, often used in garments and upholstery.

Non-wovens are known for their stability and durability. Although they usually have industrial applications (or for domestic use), they are also important in fashion (garment construction).

Conclusion

Weaving, knitting and non-woven construction techniques offer a vast array of fabric possibilities, each with unique strengths and applications. So whether it’s the crisp, structured nature of woven fabrics or the soft, stretchy feel of knits, understanding fabric construction methods will help you choose the right material for your next sewing project.

Useful links:

You will find information on the fibre types i.e. the raw materials that fabrics are made from, in my blogs on natural, synthetic and man-made fibres.

Sewing Sustainably: A Stitch Towards a Greener Future

Understanding the Basics of Fabric Construction – Fibre2Fashion